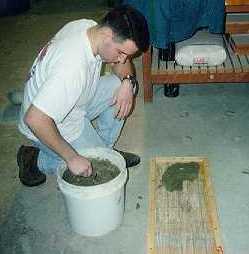

Testing was an essential aspect of creating a canoe that was both lightweight and durable. This phase included testing both the mix and the reinforcement design. Testing was performed on the concrete mixes and two reinforced sections.

Compression tests were performed on all fifteen mixes according to ASTM C39-86 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. The selected mix shows a compressive strength of 4469.2 psi. The following table summarizes these results.

Bending tests were performed on the two composite sections by third point loading. This type of loading provides pure bending moment at the center of the specimen. The average failure load was 116 pounds and the maximum moment was calculated to be 101.5 ft.-lbs.

The concrete mix selected was mix #5. This mix contains equal portions of eccospheres and Norlite. This design was selected based on the test results that indicated high strength and workability. Mixtures that incorporated vermiculite and styrofoam yielded undesirable results. Observations showed that the styrofoam did not bond well with the concrete. The vermiculite caused the heat of hydration to rise, hence, the mixture hardened prematurely.

Please direct all comments, suggestions, and queries about this page to CE-Webmaster